-

How to choose the size of reflow soldering? What temperature zone is more suitable?

Many electronics factories think that purchasing a larger reflow soldering machine can meet the general performance requirements, but it usually costs a lot of money and sacrifices the space occupied. 8 to 10 zone reflow and faster belt speeds may be the best solution in a high volume production ...Read more -

What is the difference between reflow soldering and wave soldering? Which one is better?

Today’s society is developing newer technologies every day, and these advancements can be clearly seen in the manufacture of printed circuit boards (PCBs). The design phase of a PCB consists of several steps, and among these many steps, soldering plays a vital role in determining the qualit...Read more -

How to Identify and Respond to 6 Types of PCB Fogging Coating Conformal Coating Defects

Given the variables involved in the conformal coating process (e.g. coating formulation, viscosity, substrate variation, temperature, air mixing, contamination, evaporation, humidity, etc.), coating defect issues can often arise. Let’s take a look at some common problems that can arise when...Read more -

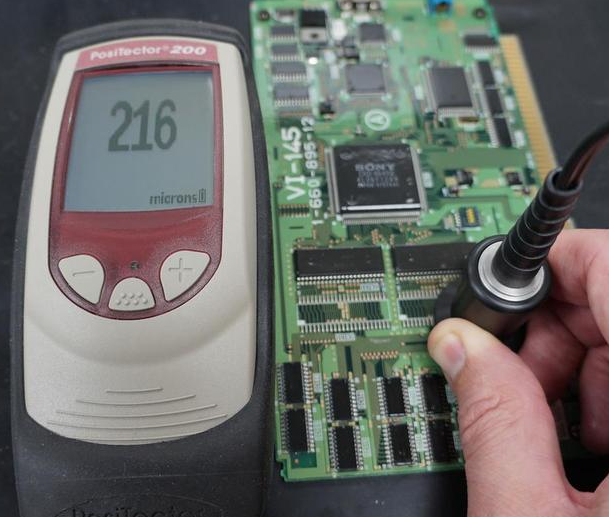

PCB conformal paint coating thickness standard and tool usage method

Standard requirements for coating thickness of PCB conformal paint The normal coating thickness of most circuit board products is 25 to 127 microns, and the coating thickness of some products is lower. How to measure with the tool Circuit boards must be protected with the thinnest possible coatin...Read more -

IC is a key component of a printed circuit board, how to determine whether it is new or used?

1. Check the part body table If a used part has been polished, it can be viewed under a magnifying glass and there will be tiny scratches on the surface. If the surface is painted, it will look bright without the plastic texture. 2. Check the printed text High-quality producers use laser printers...Read more -

How artificial intelligence is the next frontier in PCB manufacturing?

Let’s talk about something cutting-edge today, artificial intelligence. At the beginning of the manufacturing industry, it relied on manpower, and later the introduction of automation equipment greatly improved the efficiency. Now the manufacturing industry will take a further leap forward,...Read more -

Analysis of common quality defects in reflow soldering, solder spatter

The reflow soldering manufacturer Shenzhen Chengyuan Industry has found the following common problems in reflow soldering for a long time. The following are some common soldering problems, as well as suggestions for maintenance and prevention: 1. The surface of the solder joint appears frosted, c...Read more -

PCB conformal coating and PCB encapsulation, which one would you choose?

With the rapid development of the electronics industry, the use of PCBs has also increased exponentially. However, its use in different applications means that PCBs are subject to different environmental conditions. Where the PCB is exposed to moisture or harsh chemicals, performance may be of co...Read more -

How Novices Use Reflow Ovens

Reflow ovens are used in Surface Mount Technology (SMT) manufacturing or semiconductor packaging processes. Typically, reflow ovens are part of an electronics assembly line, including printing and placement machines. The printing machine prints solder paste on the PCB, and the placement machine p...Read more -

Which one is better for the three anti-paint coating machine, and how much is it?

In recent years, with the rapid development of electronic technology, especially computer hardware, the R&D and manufacturing of CNC systems for industrial production automation technology has become an emerging technology that has rapidly developed in the high-tech field. Its development has...Read more -

Analysis of Factors of Uneven Heating in Reflow Soldering

Chengyuan Industry has found in long-term practice that the main reasons for uneven heating during reflow soldering are as follows. The first is the difference in the heat capacity of the components, the second is the marginal influence of the conveyor belt or heater, and the last is the product ...Read more -

Causes and solutions of reflow solder balls

The reflow soldering manufacturer Chengyuan found in the long-term production and manufacturing that the main reasons for the reflow solder beads are as follows: 1. The quality of soldering largely depends on the solder paste The metal content in the solder paste, the degree of oxidation of the m...Read more