Reflow soldering (reflow soldering/oven) is the most widely used surface component soldering method in the SMT industry, and another soldering method is wave soldering (Wave soldering). Reflow soldering is suitable for SMD components, while wave soldering is suitable for For pin electronic components. Next time I will specifically talk about the difference between the two.

Reflow Soldering

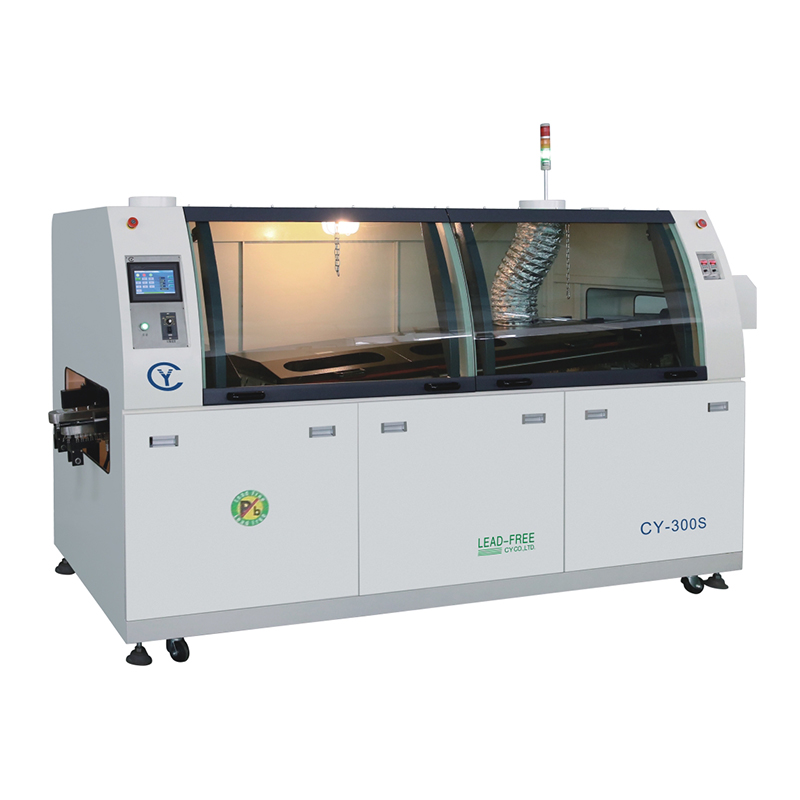

Wave Soldering

Reflow soldering is also a reflow soldering process. Its principle is to print or inject an appropriate amount of solder paste (Solder paste) on the PCB pad and mount the corresponding SMT chip processing components, and then use the hot air convection heating of the reflow oven to heat the tin The paste is melted and formed, and finally a reliable solder joint is formed by cooling, and the component is connected to the PCB pad, which plays the role of mechanical connection and electrical connection. The reflow soldering process is relatively complicated and involves a wide range of knowledge. It belongs to a new technology interdisciplinary. Generally speaking, reflow soldering is divided into four stages: preheating, constant temperature, reflow, and cooling.

1. Preheating zone

Preheating zone: It is the initial heating stage of the product. Its purpose is to heat the product rapidly at room temperature and activate the solder paste flux. It is also to avoid component heat caused by rapid high-temperature heating during the subsequent stage of immersion tin. A heating method necessary for damage. Therefore, the heating rate is very important to the product, and it must be controlled within a reasonable range. If it is too fast, thermal shock will occur, and the PCB board and components will be subjected to thermal stress, causing damage. At the same time, the solvent in the solder paste will evaporate quickly due to rapid heating. If it is too slow, the solder paste solvent will not be able to volatilize fully, which will affect the soldering quality.

2. Constant temperature zone

Constant temperature zone: its purpose is to stabilize the temperature of each component on the PCB and reach a consensus as much as possible to reduce the temperature difference between the components. At this stage, the heating time of each component is relatively long. The reason is that small components will reach equilibrium first due to less heat absorption, and large components will need enough time to catch up with small components due to large heat absorption. And ensure that the flux in the solder paste is fully volatilized. At this stage, under the action of flux, oxides on pads, solder balls and component pins will be removed. At the same time, flux will also remove oil on the surface of components and pads, increase the soldering area, and prevent components from being oxidized again. After this stage is over, each component should be kept at the same or similar temperature, otherwise there may be poor soldering due to excessive temperature difference.

The temperature and time of the constant temperature depend on the complexity of the PCB design, the difference in component types and the number of components, usually between 120-170 ° C, if the PCB is particularly complex, the temperature of the constant temperature zone should be determined with the softening temperature of rosin as a reference, the purpose is To reduce the soldering time in the back-end reflow zone, the constant temperature zone of our company is generally selected at 160 degrees.

3. Reflow zone

The purpose of the reflow zone is to make the solder paste reach a molten state and wet the pads on the surface of the components to be soldered.

When the PCB board enters the reflow zone, the temperature will rise rapidly to make the solder paste reach a melting state. The melting point of the lead solder paste Sn:63/Pb:37 is 183°C, and the lead-free solder paste Sn:96.5/Ag:3/Cu: The melting point of 0.5 is 217°C. In this area, the heat provided by the heater is the most, and the furnace temperature will be set to the highest, so that the temperature of the solder paste will rise to the peak temperature quickly.

The peak temperature of the reflow soldering curve is generally determined by the melting point of the solder paste, the PCB board, and the heat-resistant temperature of the component itself. The peak temperature of the product in the reflow area varies according to the type of solder paste used. Generally speaking, there is no The highest peak temperature of lead solder paste is generally 230-250°C, and that of leaded solder paste is generally 210-230°C. If the peak temperature is too low, it will easily cause cold welding and insufficient wetting of solder joints; if it is too high, epoxy resin type substrates will And the plastic part is prone to coking, PCB foaming and delamination, and it will also lead to the formation of excessive eutectic metal compounds, making the solder joints brittle, weakening the welding strength, and affecting the mechanical properties of the product.

It should be emphasized that the flux in the solder paste in the reflow area is helpful to promote the wetting of the solder paste and the solder end of the component at this time, and reduce the surface tension of the solder paste. However, due to the residual oxygen and metal surface oxides in the reflow furnace, The promotion of flux acts as a deterrent.

Usually a good furnace temperature curve must meet the peak temperature of each point on the PCB to be as consistent as possible, and the difference should not exceed 10 degrees. Only in this way can we ensure that all soldering actions have been successfully completed when the product enters the cooling zone.

4. Cooling zone

The purpose of the cooling zone is to rapidly cool the melted solder paste particles, and quickly form bright solder joints with a slow arc and full tin content. Therefore, many factories will control the cooling zone, because it is conducive to the formation of solder joints. Generally speaking, too fast cooling rate will make the molten solder paste too late to cool and buffer, resulting in tailing, sharpening and even burrs on the formed solder joints. Too low cooling rate will make the basic surface of the PCB pad surface The materials are mixed into the solder paste, which makes the solder joints rough, empty soldering and dark solder joints. What's more, all the metal magazines on the soldering ends of the components will melt in the soldering joints, causing the soldering ends of the components to resist wetting or poor soldering. Affects the soldering quality, so a good cooling rate is very important for solder joint formation. Generally speaking, solder paste suppliers will recommend a solder joint cooling rate of ≥3°C/S.

Chengyuan Industry is a company specializing in providing SMT and PCBA production line equipment. It provides you with the most suitable solution for you. It has many years of production and research experience. Professional technicians provide installation guidance and after-sales door-to-door service, so that you have no worries.

Post time: Mar-06-2023