02

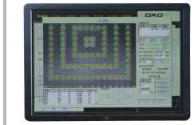

Using uniform ring light and high brightness coaxial light, with promise brightness adjustment function, then all types of Mark points can be well recognized (Including the rugged Mark points), applicable for tin plating, coppering, gold plating, tin spraying, FPC and other types PCB with of different colors. With GKG patent mathematical model, able to ensure high accuracy

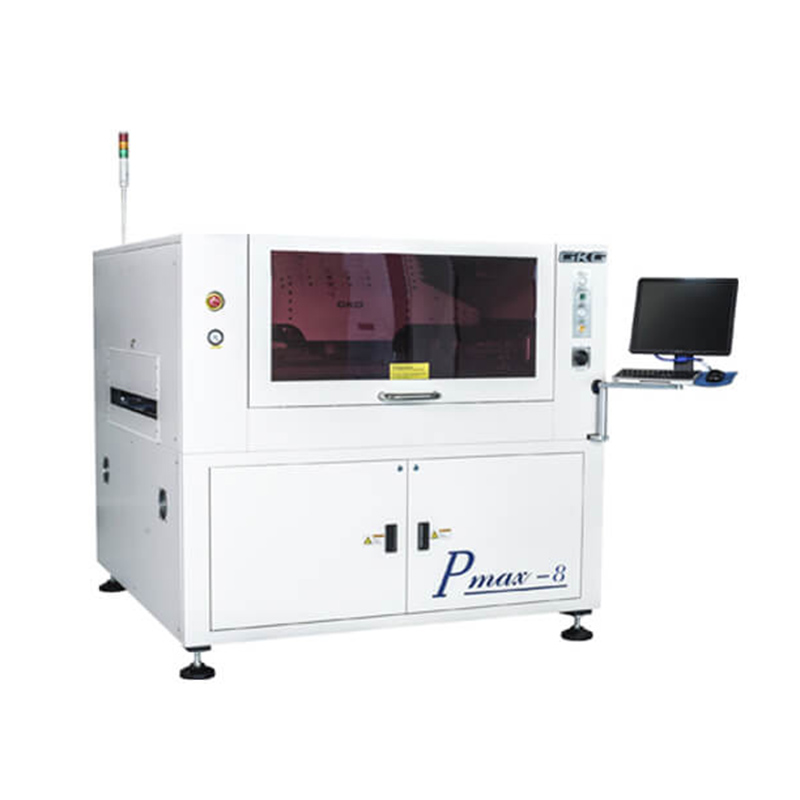

Specifications:

Fast Smart Modular Mounter

| Item | H1200 | |

| Repeat Position Accuracy | ±0.01mm(Test data and method are available) | |

| Printing Accuracy | ±0.025mm(Test data and method are available) | |

| Printing Speed / Cycle Time | <10s (Exclude Printing & Cleaning) | |

| Products Changeover | <5Min | |

| Screen Stencil Size/Min-Max | 720mm X300mm-1500mm X750mm | |

| Screen Stencil Size/Thickness | 20mm ~ 40mm | |

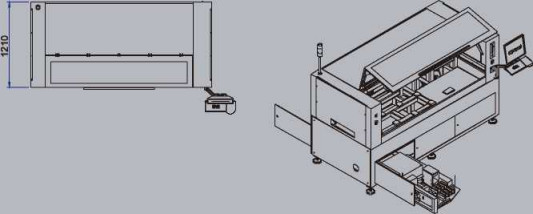

| PCB Size/Min-Max/Thickness | 80X50mm-1200X350mm/0.8~6mm | |

| PCB Warpage Ratio | <1%(Based on diagonal length) | |

| Bottom of Board Size | 15mm(Standard configuration), 25mm | |

| Edge of Board Size | 3mm | |

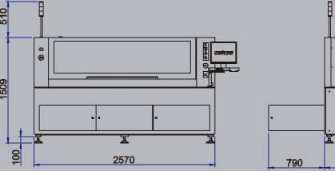

| Conveyor Height | 900±40mm | |

| Conveyor Direction | Left-Right; Right-Left; Left-Left; Right-Right | |

| Conveyor Speed | 100-1500mm/sec Programmable control | |

| Board Positioning | Support System | Magnetic pin/Side support block/Flexible automatic pin(optional) |

| Clamping System | Elastic side clamping/Vacuum nozzle/Extension-type Z-direction table setting | |

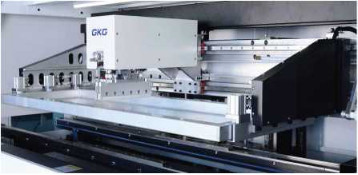

| Print head | Two indepandent Motorised printheads | |

| Squeegee Speed | 6~300mm/sec | |

| Squeegee Pressure | 0-10kg software control(closed-loop pressure feedback), pressure value visible | |

| Squeegee Angle | 60°(Standard )/55°/45° | |

| Squeegee Type | Steel squeegee (standard), rubber squeegee, and other types of squeegee shall be customized. | |

| Steel Mesh Separation Speed | 0.1~20mm/sec Programmable Control | |

| Cleaning Method | Dry-type, wet-type, vacuum-type ( Programmable combination of Cleaning methods) | |

| Table Adjustment Range | X/Y:±10mm;θ:±2° | |

| Type of Fiducial Point | Standard geometry shape of fiducial point, bonding pad / Stencil hole | |

| Camera System | Single digital camera for upward/downward vision system | |

| Air Pressure | 4~6Kg/cm2 | |

| Air Consumption | Approx 0.07m3 /min | |

| Control Method | PC Control | |

| Power Supply | AC:220±10%,50/60HZ 1Φ 1.5KW | |

| Machine Dimensions/Weight | Depends on exactly model | |

| Operation Temperature | -20°C ~ +45°C | |

| Operation Humidity | 30%~60% | |