01

● Fault diagnosis function, can display each fault, display and store in automatic alarm list

● Control procedures can automatically generate and backup the data report, easy to ISO 9000 management.

● Focused on improving environmental performance of equipment, including a new energy-efficient (duct structure), significantly reducing energy consumption, lower energy consumption and carbon emissions.

● Windows7 operating system, Chinese and English interface switch, easy to operate.

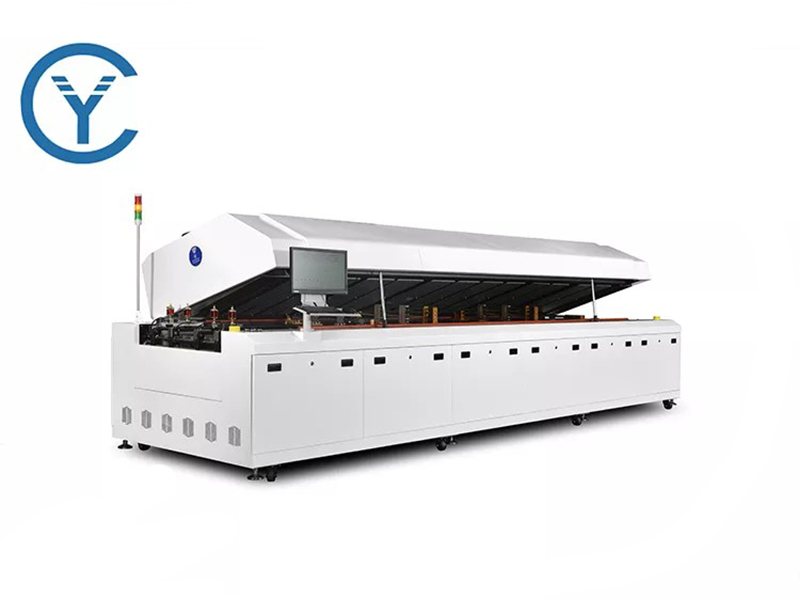

● CY series not only meets the highest requirements of lead-free and welding, but also guarantees high quality welding effect, and improves heat conduction technology to avoid overheating of electronic parts on PCB board.

Specifications:

| F series double rail Reflow soldering technology parameters | |||

| Series | F series single rail | ||

| Model | CY-F820 | CY-F1020 | CY-F1220 |

| Heating zones | UP 8 / down 8 | Up 10 / down 10 | Up 12 / down 12 |

| Cooling zones | Up 2 /down 2 or UP 3 / down 3(optional) | ||

| Heating zone length | 2900mm | 3600mm | 4400mm |

| PCB maximum width | Rail type:400mm Belt type: 550mm | ||

| Rail wide adjust range | 50-400mm | ||

| Transport direction | L→R(R→L) | ||

| Fixing method of transport guide rail | Front(optional:back end) | ||

| Conveyor height | Belt:900±20mm,Chain:900±20mm | ||

| Transmission way | Chain+ belt | ||

| Conveyor speed | 300-2000mm/Min | ||

| The power supply | 3-phase 380V 50 / 60Hz | ||

| Starting power | 35Kw | 48Kw | 68Kw |

| Normal work consumed power | Approx.7.5Kw | Approx.8.5Kw | Approx.10Kw |

| Heating up time | About 15-20minutes | ||

| The temperature control range | Room Temperature-350℃ | ||

| Temperature control mode | Full computer PID closed loop control, SSR drive | ||

| The whole machine control mode | Computer +PLC | ||

| The temperature control precision | ±1℃ | ||

| The deviation of PCB temperature distribution | ±1-2℃ | ||

| Cooling way | Air machine: air cooling, nitrogen machine: water cooling | ||

| Abnormal alarm | Abnormal temperature (ultra high or ultra low after constant temperature) | ||

| Three color light | Yellow - temperature rise; Green - constant temperature; Red anomaly | ||

| Weight | Approx.1700Kg | Approx.1900Kg | Approx.1900Kg |

| Dimensions(mm) | 5050×1400×1450 | 5750×1400×H450 | 6480×1400×H450 |

| Exhaust air requirements | 10 cubic / min 2 channel ∮ 200mm | ||