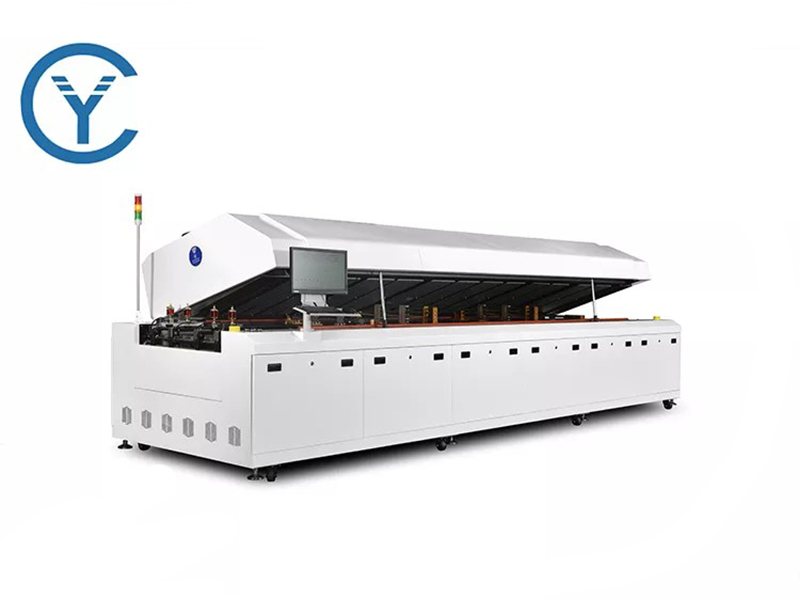

Chinese wholesale wave soldering equipment - CY Lead-free reflow soldering oven CY– F820 – Chengyuan Detail:

● Fault diagnosis function, can display each fault, display and store in automatic alarm list

● Control procedures can automatically generate and backup the data report, easy to ISO 9000 management.

● Focused on improving environmental performance of equipment, including a new energy-efficient (duct structure), significantly reducing energy consumption, lower energy consumption and carbon emissions.

● Windows7 operating system, Chinese and English interface switch, easy to operate.

● CY series not only meets the highest requirements of lead-free and welding, but also guarantees high quality welding effect, and improves heat conduction technology to avoid overheating of electronic parts on PCB board.

Specifications:

| F series double rail Reflow soldering technology parameters | |||

| Series | F series single rail | ||

| Model | CY-F820 | CY-F1020 | CY-F1220 |

| Heating zones | UP 8 / down 8 | Up 10 / down 10 | Up 12 / down 12 |

| Cooling zones | Up 2 /down 2 or UP 3 / down 3(optional) | ||

| Heating zone length | 2900mm | 3600mm | 4400mm |

| PCB maximum width | Rail type:400mm Belt type: 550mm | ||

| Rail wide adjust range | 50-400mm | ||

| Transport direction | L→R(R→L) | ||

| Fixing method of transport guide rail | Front(optional:back end) | ||

| Conveyor height | Belt:900±20mm,Chain:900±20mm | ||

| Transmission way | Chain+ belt | ||

| Conveyor speed | 300-2000mm/Min | ||

| The power supply | 3-phase 380V 50 / 60Hz | ||

| Starting power | 35Kw | 48Kw | 68Kw |

| Normal work consumed power | Approx.7.5Kw | Approx.8.5Kw | Approx.10Kw |

| Heating up time | About 15-20minutes | ||

| The temperature control range | Room Temperature-350℃ | ||

| Temperature control mode | Full computer PID closed loop control, SSR drive | ||

| The whole machine control mode | Computer +PLC | ||

| The temperature control precision | ±1℃ | ||

| The deviation of PCB temperature distribution | ±1-2℃ | ||

| Cooling way | Air machine: air cooling, nitrogen machine: water cooling | ||

| Abnormal alarm | Abnormal temperature (ultra high or ultra low after constant temperature) | ||

| Three color light | Yellow – temperature rise; Green – constant temperature; Red anomaly | ||

| Weight | Approx.1700Kg | Approx.1900Kg | Approx.1900Kg |

| Dimensions(mm) | 5050×1400×1450 | 5750×1400×H450 | 6480×1400×H450 |

| Exhaust air requirements | 10 cubic / min 2 channel ∮ 200mm | ||

Product detail pictures:

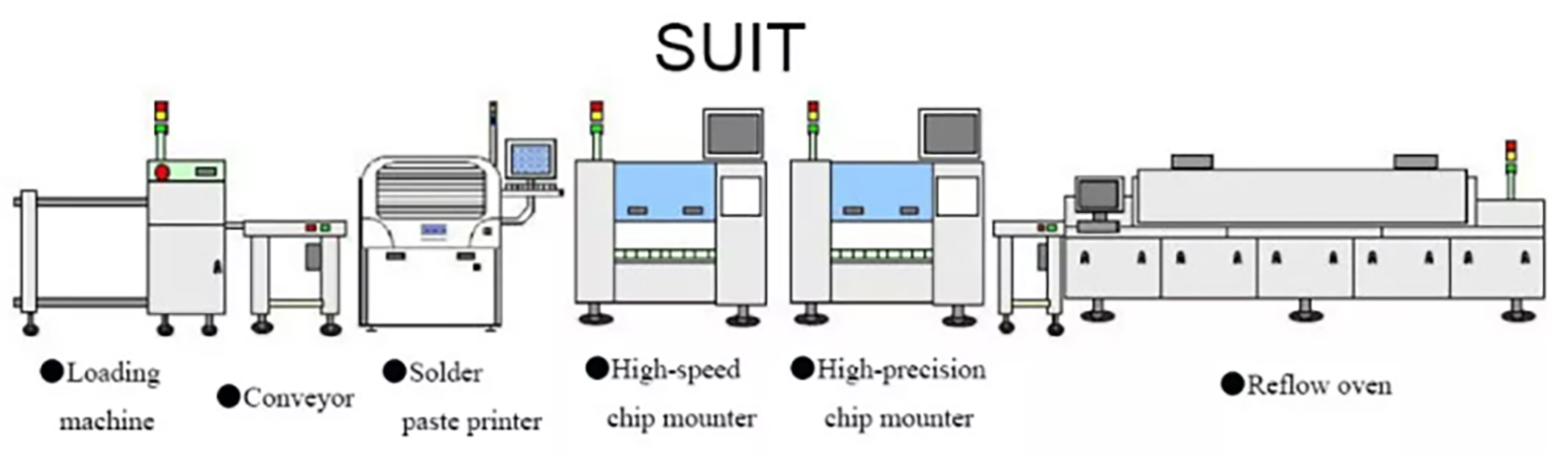

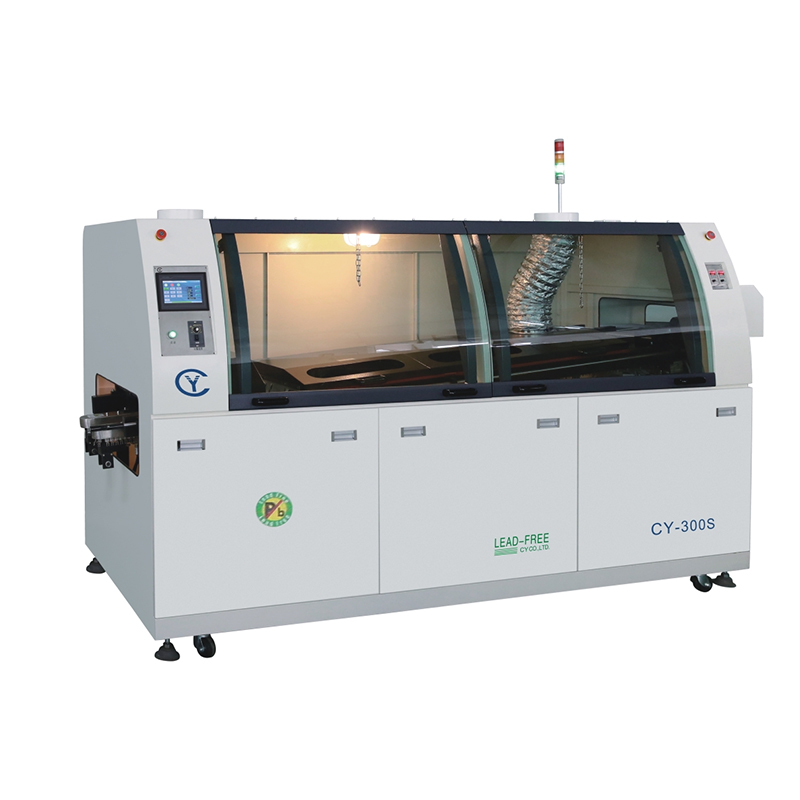

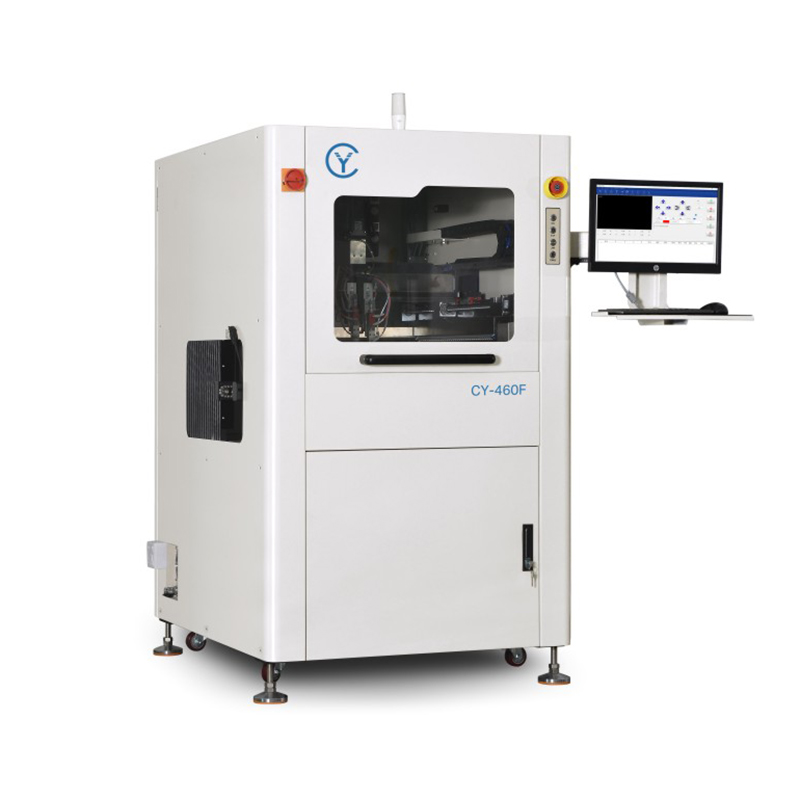

Related Product Guide:

Persisting in "High top quality, Prompt Delivery, Aggressive Price", now we have established long-term cooperation with customers from the two overseas and domestically and get new and aged clients' large comments for Chinese wholesale wave soldering equipment - CY Lead-free reflow soldering oven CY– F820 – Chengyuan , The product will supply to all over the world, such as: Algeria, Toronto, Cape Town, Only for accomplishing the good-quality product to meet customer's demand, all of our products have been strictly inspected before shipment. We always think about the question on the side of the customers, because you win, we win!

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.